charpy v-notch impact energy testing|charpy impact test results explained : service Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact . WEBFind up to date company insights for Creditime. Get Contact details, financial insights, industry benchmarks, competitors from creditsafe.com

{plog:ftitle_list}

Pinnacle BankONeill, NE. 429 E Douglas. PO Box 470. ONeil.

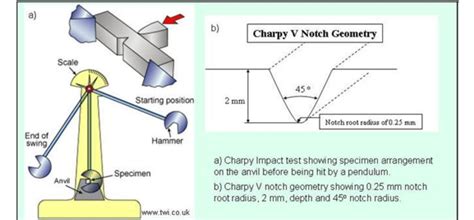

The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event).The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .

The deformation energy required for fracturing the specimen is called notch impact energy \(K\) (\(KV\): specimens with V-notch; \(KU\): specimens with U-notch). The notch impact energy can therefore be .

In this study, based on the load-bearing form of the V-notch specimens subjected to the pendulum lateral impact, and the response process of structural deformation and .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .There are two main forms of impact test, the Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed. The amount of energy absorbed in fracturing the test piece is .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated. The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. . Note Energy: Most Charpy testing machines will have a dial graded in joules. The .For the assessment of material toughness, international standards commonly require Charpy V-notch (CVN) impact testing of the steel product. A required toughness level is commonly expressed for a particular test temperature (which may be different to the lowest anticipated service temperature) at which a minimum CVN impact energy value (KV min .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.

The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch.The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results. 1. Introduction. Impact energy characterizes the ability of a structure to consume energy through deformation and fracture under impact load. The impact energy A k, a value measured by the Charpy impact test, is mainly used to control the quality of metallurgical and thermal processing products and determine the ductile-brittle transition temperature of .

energy absorbed by the test piece during the test Note 1 to entry: . Kalthoff J.F., Gregor M., Instrumented Impact Testing of Subsize Charpy V-Notch Specimens”, Small Specimen Test Techniques, ASTM STP 1329, Corwin W.R., Rosinski S.T. and van Walle E., Eds., .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which . specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holderNotch toughness is an indication of the capacity of a steel to absorb energy when a stress concentrator or notch is present. The notch toughness of a steel product is the result of a number of interactive effects, including composition, deoxidation and steelmaking practices, solidification, and rolling practices, as well as the resulting microstructure. Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and . specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to .

CHARPY V-NOTCH IMPACT ENERGY, AND YIELD STRENGTH FOR ASTM A723 STEEL J. A. KAPP T1 J. IL UNDERWOOD MARCH 1992 US ARMY ARMAMENT RESEARCH, . "Impact Testing of Metels," ASTM STP 466, The American Society for Testing and Materials, Philadelphia, PA, 1970, pp. 281-302. 2. S.T. Rolfe and S.R. Novak, "Review of Developments .

Charpy impact test piece (V-notch, U-notch) Method for Charpy impact test of carbon fiber reinforced plastics: Test piece for flatwise impact . In the same way as the Charpy impact test, absorbed energy is measured by measuring the angle which the hammer is lifted to and the angle which the hammer swings up to as a result of inertia after . Fig. 2 shows the measured toughness-temperature properties for the tested welds in terms of conventional Charpy V-notch impact energy (T-L orientation) and also includes the measured . Conventional Charpy-V notch impact testing was also conducted on the test welds to characterize their ductile-to-brittle transition and to correlate the CVN .Two standardized tests, the Charpy and Izod, are commonly used to measure Impact Energy (sometimes referred to as Notch Toughness). The Charpy V-notch (CVN) technique is most commonly used in the United States. For both Charpy and Izod, a V-notch is machined into a bar specimen with a square cross-section. A standard V-notch test apparatus is . It is also known as Charpy V notch test. Charpy testing is a method for determining the relative impact strength of metals. It is also known as Charpy V notch test. . such as the effect of heat treatments and aging. However, notch impact energy cannot be used to assess material fracture energy alone. Other parameters must be evaluated to .

As was written, toughness can be measured by the Charpy test or the Izod test.These two standardized impact tests, the Charpy and the Izod are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used. Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.

fieldpiece flue gas analyzer

WEB20 de fev. de 2024 · League of Legends Stats! Check your profile and weapon statistics. View the top League of Legends players on our leaderboards and how you perform by comparison.

charpy v-notch impact energy testing|charpy impact test results explained